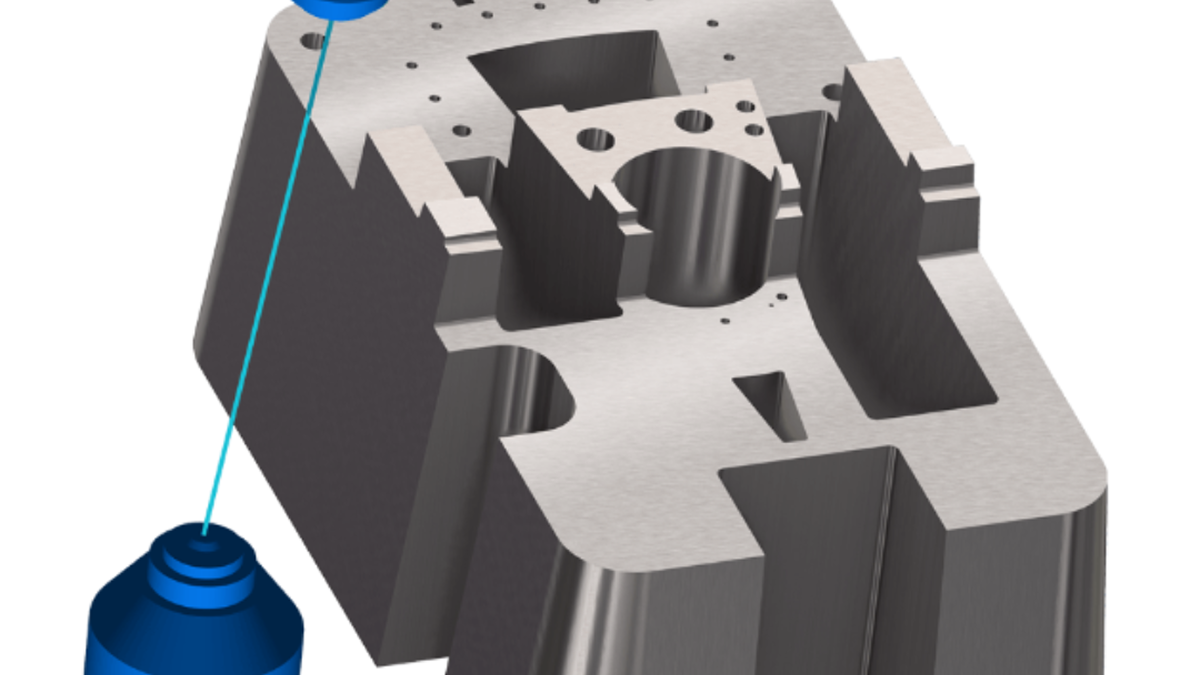

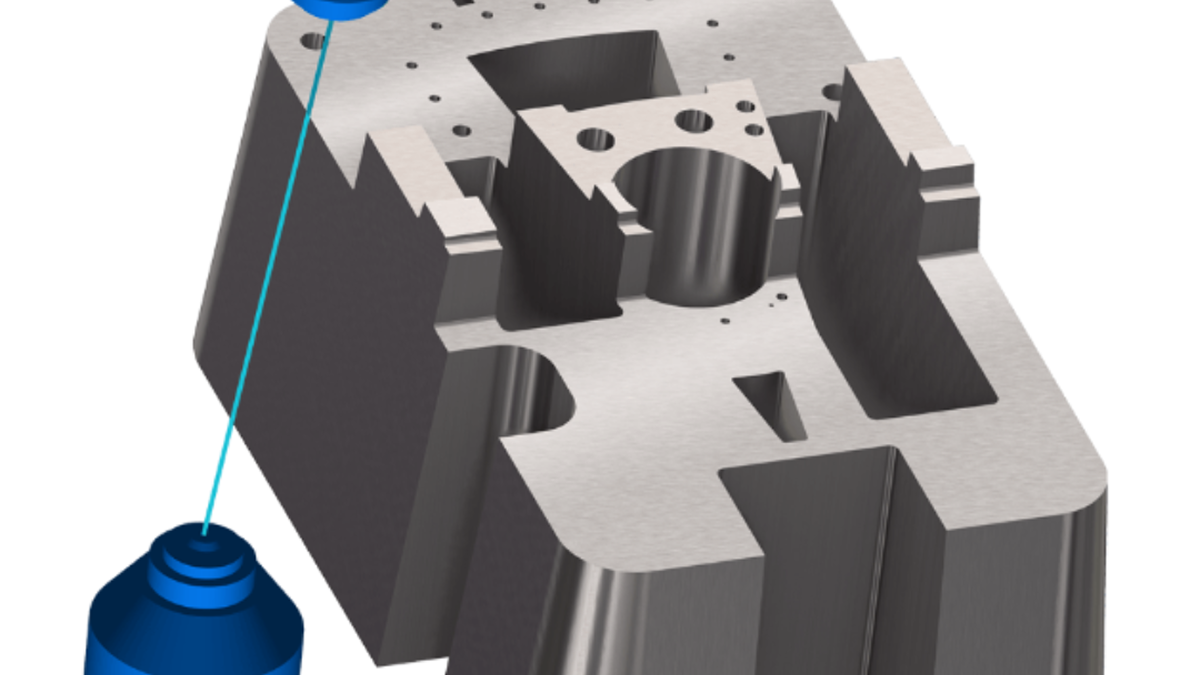

Fast, easy, and productive—the way programming should be. Mastercam Wire is a solution for programming CNC Wire EDM machines.

Mastercam’s suite of 2-axis and 4-axis wirepaths lets you choose the best method for the results you need, with control over the wire motion, angle, entries and exits, and much more. And you get that control in a clear, easy to understand way.

- Full-featured design capabilities support any combination of modeling, from wireframe to surfaces to solid models.

- Automatic lead-in and lead-out strategies, fast, flexible tab creation, and no core cutting make Mastercam Wire a powerful tool for quickly programming parts.

- Intelligent NC programming lets you build a library of machining strategies that automatically adapt to new models.

- Mastercam Wire compliments the functionality of other products such as Mastercam Mill and Lathe.

Learn more.

https://cutt.ly/AXSYSBLOG_WIRE

Key Features of Mastercam Wire

Mastercam Wire is designed to streamline the programming process for CNC Wire EDM machines with its intuitive interface and robust feature set. Users benefit from advanced capabilities such as customizable wire paths, which allow for precise control over the machining process, ensuring that even the most complex geometries are executed with accuracy.

In addition to customizable wire paths, Mastercam Wire offers automatic lead-in and lead-out strategies, which significantly reduce setup time. The software's ability to handle both 2-axis and 4-axis wirepaths means that manufacturers can easily adapt to varying project requirements, enhancing overall productivity and efficiency in the production workflow.

Benefits of Using Mastercam Wire for CNC Programming

Utilizing Mastercam Wire for CNC programming brings numerous advantages, including increased productivity and reduced error rates. The software's automatic programming features minimize manual input, allowing operators to focus on other critical tasks while ensuring high-quality outputs.

Moreover, Mastercam Wire's compatibility with other Mastercam products means that users can leverage existing workflows and tools, creating a seamless integration within their manufacturing processes. This interconnectedness not only saves time but also enhances the overall effectiveness of CNC operations.

Real-World Applications of Mastercam Wire

Mastercam Wire is widely adopted across various industries, including aerospace, automotive, and medical device manufacturing. Its versatility allows it to cater to a broad spectrum of applications, from creating intricate components to producing high-precision parts that meet stringent industry standards.

For instance, in the aerospace sector, manufacturers utilize Mastercam Wire to fabricate lightweight yet durable components that are crucial for aircraft performance. The software’s capabilities enable engineers to design and produce parts that are both complex and reliable, underscoring its importance in high-stakes environments.

Customer Support and Training for Mastercam Wire Users

Axsys Incorporated offers comprehensive customer support and training for Mastercam Wire users, ensuring that clients can maximize the software's potential. Dedicated training sessions, both online and in-person, are available to help users understand the full range of features and functionalities.

Additionally, ongoing customer support is provided to address any technical issues or questions that may arise during the programming process. This commitment to customer service reinforces Axsys's dedication to enhancing user experience and ensuring optimal use of Mastercam Wire in various manufacturing settings.