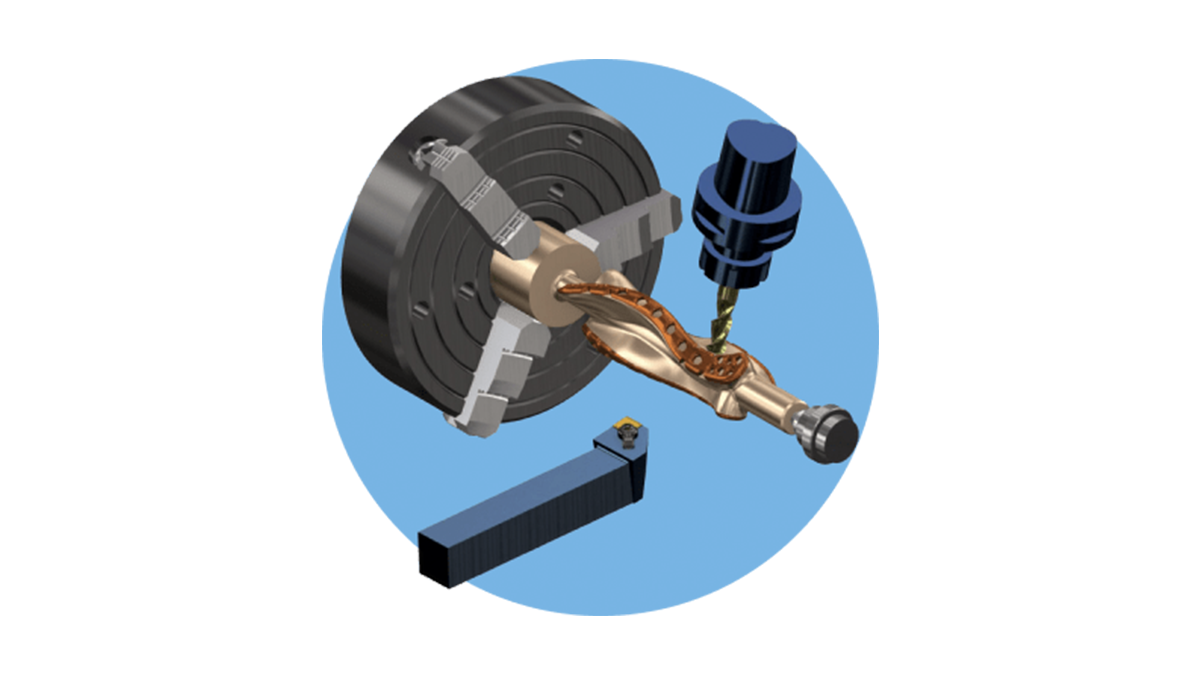

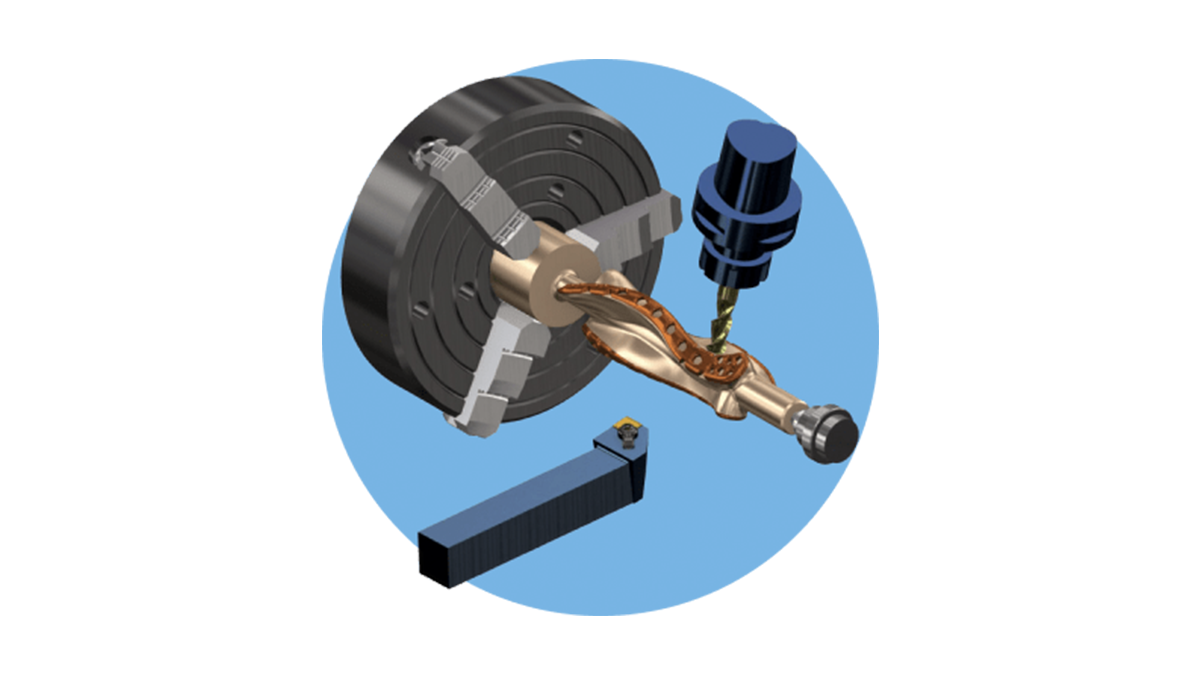

Give your shop the best possible foundation for fast and efficient milling. From general purpose methods such as optimized pocketing to highly specialized toolpaths like 5-axis turbine cutting, with Mastercam Mill, your parts are produced faster, with greater accuracy, quality, and repeatability.

Many of the products we use every day are made with the help of Mastercam Mill. This software delivers a full array of machining strategies and so much more. Mastercam milling solutions can be customized to what your shop needs today and easily scaled to meet your future manufacturing needs.

Learn more.

https://cutt.ly/MASTERCAM_MILLSOLUTIONS

Key Features of Mastercam Mill

Mastercam Mill is designed to provide a range of powerful features that enhance machining capabilities. Key functionalities include optimized pocketing, advanced toolpath generation, and support for 5-axis machining, allowing users to tackle complex geometries with ease.

These features not only improve the efficiency of the milling process but also ensure higher accuracy and quality in the finished parts. For instance, the ability to create specialized toolpaths for intricate designs enables manufacturers to reduce cycle times and increase throughput, making Mastercam Mill a vital tool in modern manufacturing environments.

Benefits of Using Mastercam Mill

Utilizing Mastercam Mill offers numerous benefits, including increased productivity, reduced operational costs, and improved part quality. By automating various aspects of the machining process, manufacturers can streamline their workflows and minimize human error.

Moreover, Mastercam Mill's scalability allows businesses to adapt their machining strategies as they grow. Whether a shop is small or large, the software can be customized to fit specific needs, ensuring that manufacturers can maintain high standards of quality and efficiency as they expand their operations.

Training and Support for Mastercam Mill Users

Axsys Incorporated provides comprehensive training and support for Mastercam Mill users, ensuring that they can fully leverage the software's capabilities. This includes online tutorials, webinars, and hands-on workshops designed to enhance user proficiency and confidence.

In addition to training, ongoing technical support is available to address any challenges users may encounter. This commitment to customer service helps manufacturers maximize their investment in Mastercam Mill, ultimately leading to better machining outcomes and customer satisfaction.

Customer Success Stories with Mastercam Mill

Many manufacturers have experienced significant improvements in their machining processes after implementing Mastercam Mill. Success stories highlight how businesses have increased production rates and enhanced product quality through the software's advanced features.

For example, a machining shop reported a 30% reduction in cycle times after adopting Mastercam Mill, allowing them to take on more projects and increase revenue. Such testimonials illustrate the tangible benefits that Mastercam Mill offers to manufacturers looking to stay competitive in a fast-paced industry.