Wire EDM offers unmatched precision and reliability in manufacturing. It cuts complex parts with electrical sparks, ensuring superior accuracy beyond blueprints.

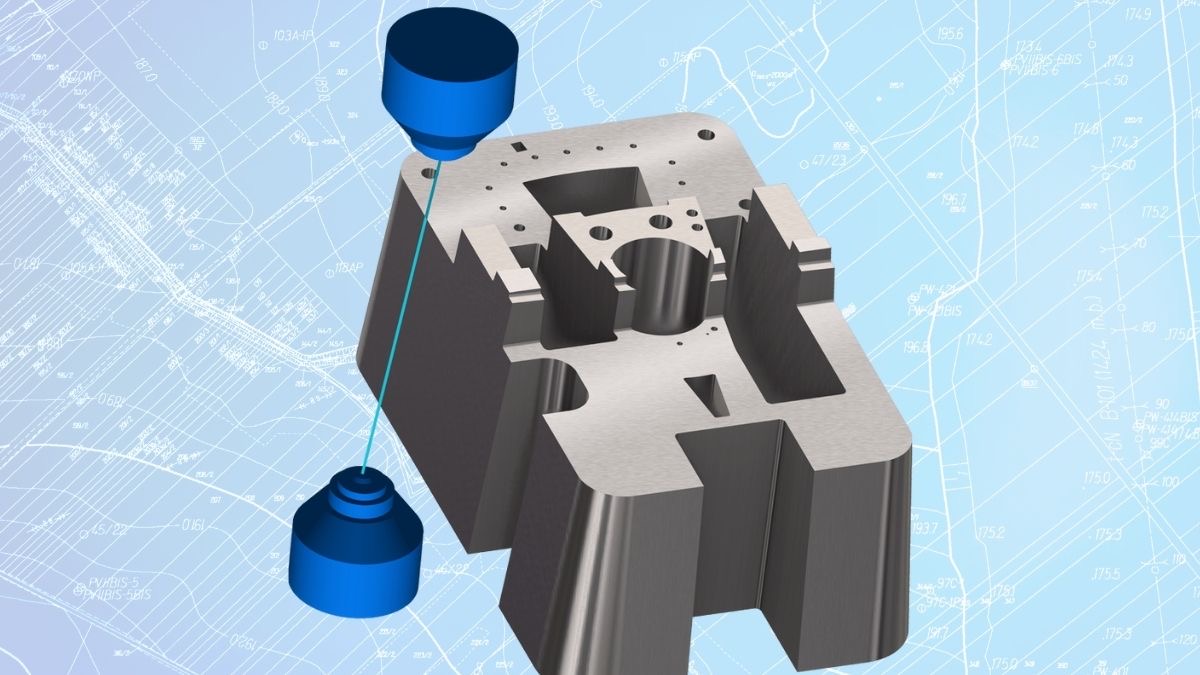

Precision manufacturing constantly strives for unmatched accuracy and consistency. Conventional machining techniques frequently face constraints in industries where precise tolerances and complex geometries are critical. In this situation, wire electrical discharge machining (Wire EDM) proves to be a game-changing technology, regularly producing dependable outcomes that greatly surpass the original blueprint specifications.

The Science of Accuracy: The Workings of Wire EDM

Fundamentally, wire EDM is a thermal process that is extremely controlled. Spooled between two guides, a continuous wire electrode—usually composed of coated copper or brass—passes through a workpiece immersed in a dielectric fluid, most often deionized water. Tiny, quick sparks leap across the tiny space between the wire and the workpiece when an electrical potential is applied. Microscopic particles of the material are melted and vaporized by the intense localized heat produced by these sparks, and the dielectric fluid subsequently flushes them away.

Several fundamental operating principles underpin Wire EDM’s dependability:

- Non-Contact Machining: This process removes material distortion, tool wear, and mechanical stresses by removing the wire’s physical contact with the workpiece. This is essential for avoiding deformities when machining thin sections, delicate parts, and pre-hardened materials.

- Precision Control: Computer Numerical Control (CNC) systems carefully regulate every step of the process. These systems ensure precise adherence to design specifications and highly repeatable results by precisely guiding the wire along a preprogrammed path.

- Constant Flushing: The dielectric fluid has two functions: it prevents short circuits and keeps the cutting zone clean by acting as an insulator, which permits the spark to occur, and it continuously flushes away eroded material. This guarantees a neat and consistent cut.

- Material Hardness Independence: The effectiveness of Wire EDM is independent of the hardness of the material, in contrast to traditional machining. Traditional tools would find it difficult or impossible to cut hardened steels, titanium, exotic alloys, and even superalloys precisely.

This set of guidelines guarantees that Wire EDM continuously creates parts with superior surface finishes and incredibly tight tolerances, frequently doing away with the need for secondary finishing processes.

Applications Requiring Constant Dependability

Wire EDM is the preferred option for many applications where dependability and strict standards are essential due to its inherent precision and non-contact nature. These consist of:

- Aerospace Components: Producing complex turbine blades, structural elements, and exact fittings where material integrity and perfect accuracy are essential.

- Medical Devices: Manufacturing tiny parts, implants, and delicate surgical instruments that call for biocompatible materials and incredibly fine features.

- Tool and Die Making: Producing intricate punches, dies, and molds for a range of industries, guaranteeing long operational life and high wear resistance because of the burr-free cuts.

- Automotive Industry: Manufacturing specialized tools, gears, and exact engine parts for the production of automobiles.

- Electronics: Machining complex parts for micro-electromechanical systems (MEMS), circuit boards, and connectors.

Did you know?

In 1943, Russian scientists B. Lazarenko and N. Lazarenko made a major advancement in machining technology by observing and developing the basic principles of Electrical Discharge Machining.

Our Dedication to Providing Outstanding Solutions

Our mission at Axsys Industrial Solutions is to enable industries to attain previously unheard-of levels of accuracy and efficiency by offering state-of-the-art manufacturing solutions. This dedication is centered on our proficiency with Wire EDM, which provides our clients with dependable and replicable outcomes for their most exacting projects. To guarantee that every component produced satisfies the highest standards of quality and performance, we make use of cutting-edge technology and extensive industry knowledge.

We encourage you to look over our extensive selection of products and services, which are intended to help you with all aspects of manufacturing, from conception to completion.

For industries requiring the highest levels of precision, Wire EDM is an essential tool due to its demonstrated dependability and exceptional results. Working with Axsys Industrial Solutions gives you access to cutting-edge technology and a team of professionals dedicated to turning your ideas into flawlessly functional parts. We are ready to help you reach your manufacturing goals with unmatched precision and effectiveness.

To discuss your unique needs and find out how we can assist you in achieving dependable, high-precision results, give Axsys Industrial Solutions a call at (248) 926-8810.