Innovations in CAD/CAM Software

The field of CAD/CAM software is continuously evolving, with innovations that enhance productivity and design capabilities. New features and tools are being developed to streamline the design process, improve accuracy, and reduce production times, making it easier for engineers and designers to bring their ideas to life.

For instance, advancements such as cloud-based CAD solutions allow for real-time collaboration among teams, regardless of location. Additionally, the integration of artificial intelligence and machine learning into CAD/CAM software is enabling smarter design recommendations and automated processes, which can significantly boost efficiency in manufacturing environments.

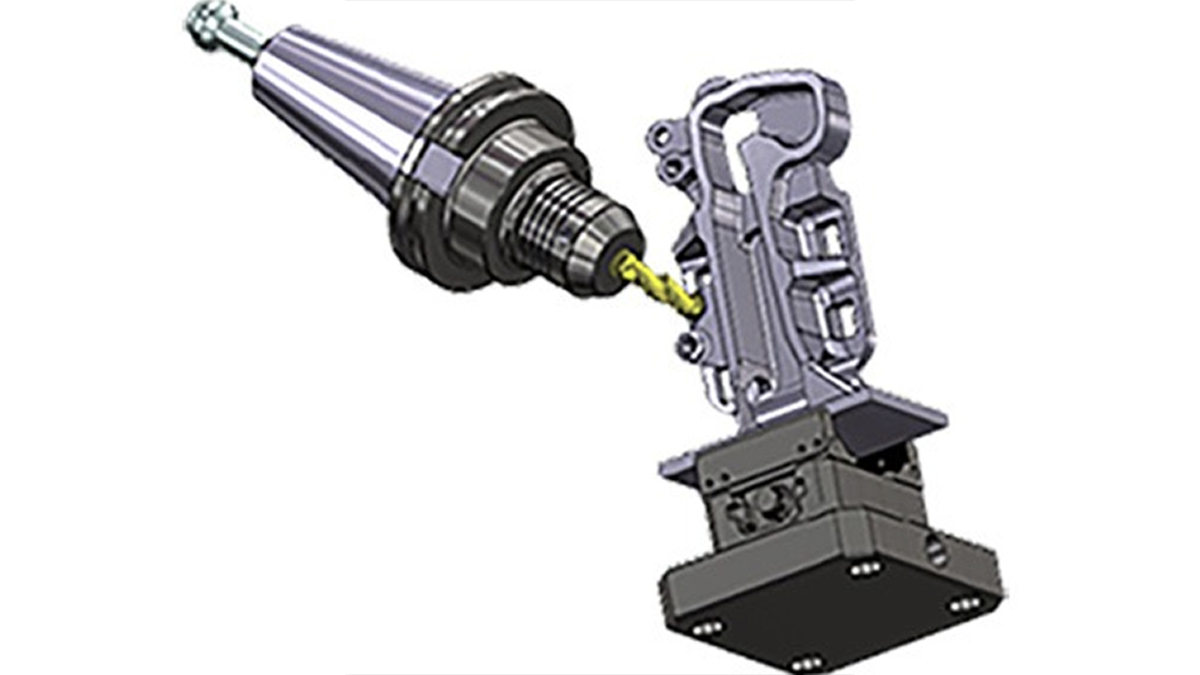

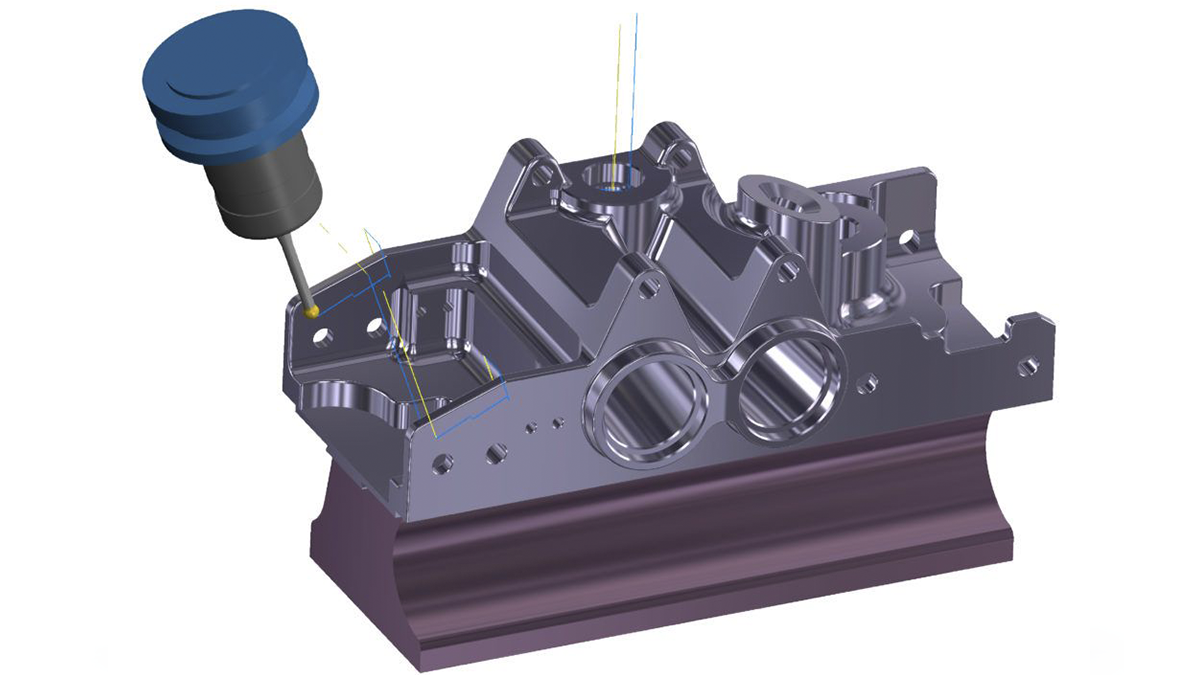

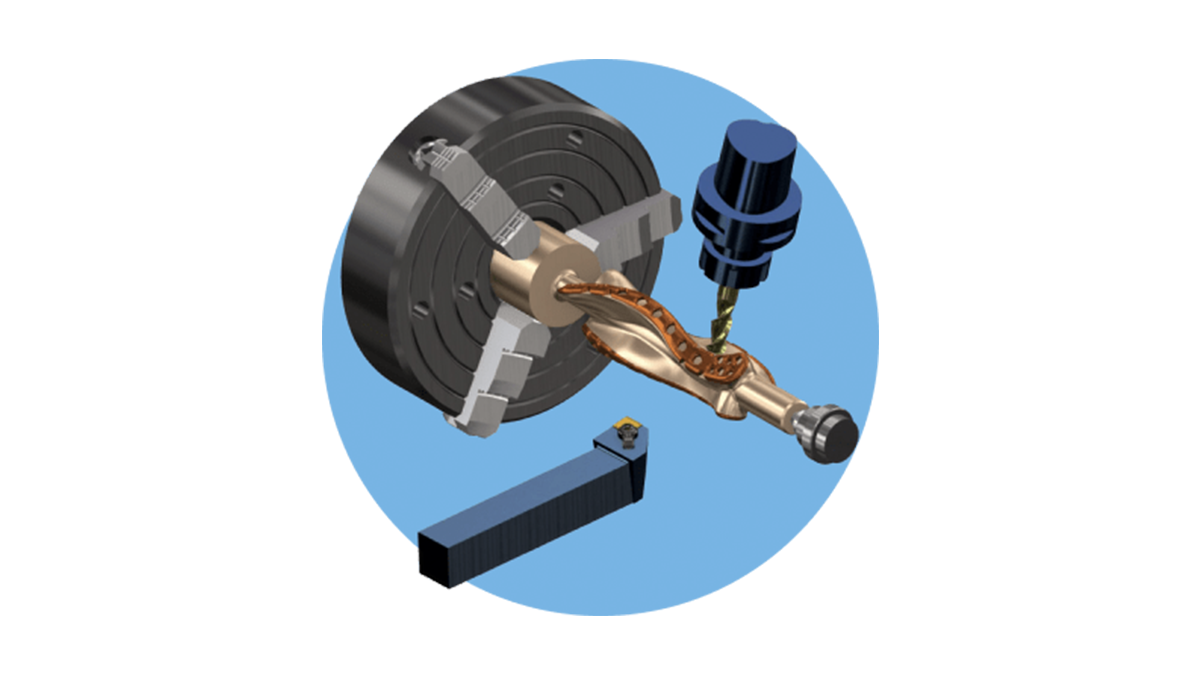

Best Practices for CNC Machining

Implementing best practices in CNC machining can lead to higher quality outputs and reduced operational costs. These practices include proper tool selection, regular maintenance of machinery, and the use of effective cutting strategies that optimize performance and minimize wear on tools.

For example, utilizing the right feed rates and speeds can enhance machining efficiency while maintaining the integrity of the material being processed. Furthermore, training operators on the latest techniques and technologies ensures that they can maximize the capabilities of the CNC machines, contributing to overall productivity improvements.

The Future of Manufacturing Technology

The future of manufacturing technology is poised for transformative changes driven by automation, IoT, and smart manufacturing. These advancements are set to create more agile and responsive manufacturing processes, allowing businesses to adapt quickly to market demands.

Emerging technologies such as additive manufacturing and robotics are reshaping traditional manufacturing paradigms. Companies that embrace these innovations can achieve greater flexibility, reduce waste, and improve product customization, ultimately leading to enhanced competitiveness in the global market.

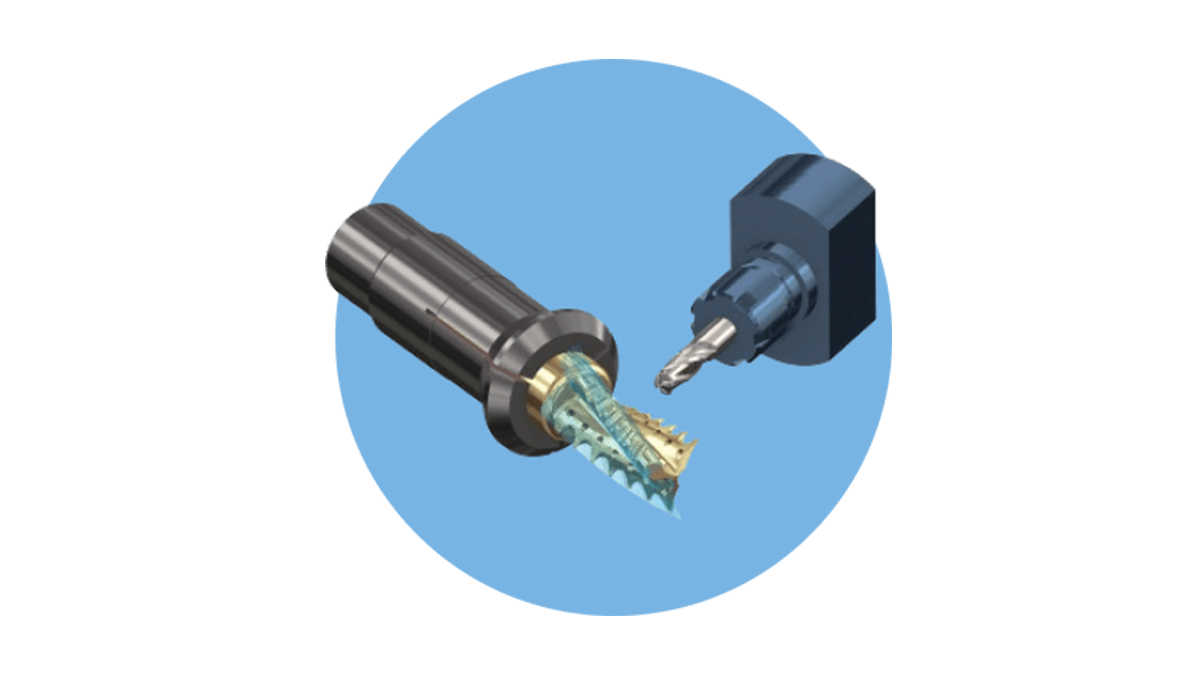

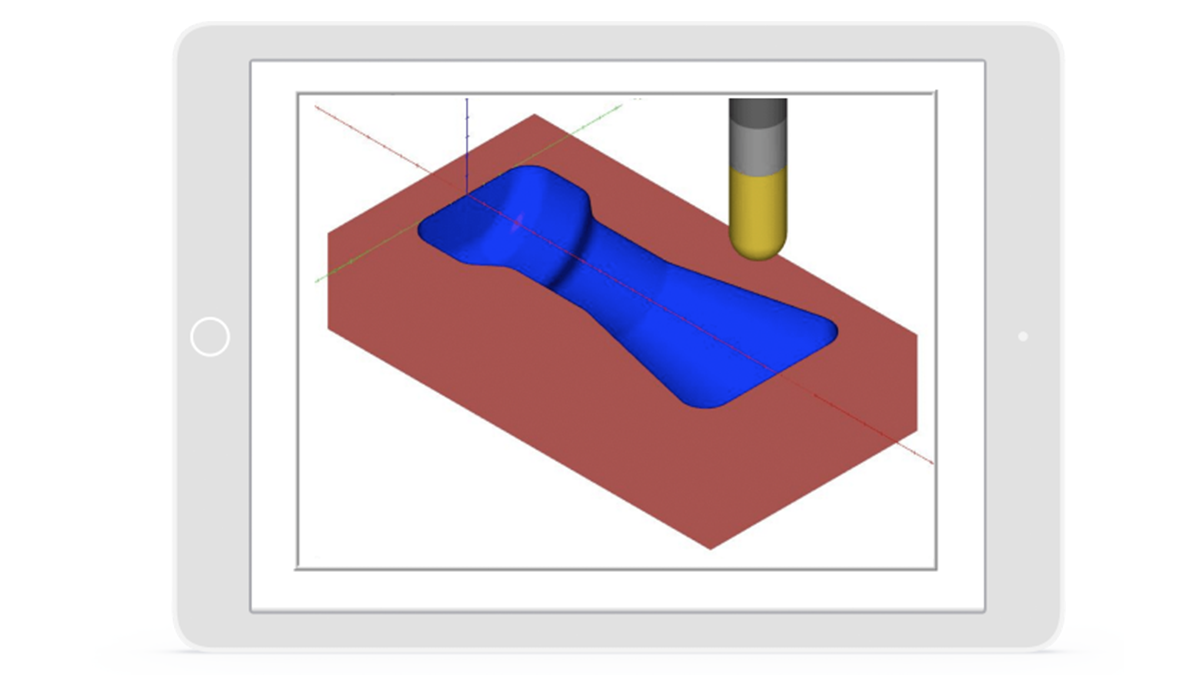

Understanding CAD/CAM Integration

Integrating CAD and CAM systems is crucial for streamlining workflows and improving productivity in manufacturing. This integration allows for seamless data transfer between design and production, ensuring that specifications are accurately translated into physical products.

For instance, when a design is modified in CAD, the changes can automatically update the CAM program, reducing the risk of errors and speeding up the production process. Such integration not only enhances efficiency but also fosters collaboration between design and manufacturing teams, leading to better overall outcomes.