CAD/CAM Helps Busy Machine Shop Produce Challenging Parts

Scottsboro, Alabama-based Avans Machine Inc. prides itself on quality and excellence, serving a broad spectrum of industries including pharmaceutical/medical, aerospace, space, and defense.

The Challenge

Finding a more universal CAM software system to meet their customers needs.

The Solution

Mastercam, the most robust CAD/CAM software for machining applications.

Benefits

- OptiRough enables a more efficient, collision-aware roughing strategy.

- Backplot checks toolpaths for collisions and other issues.

- Verify finds efficiencies in stock removal and proactively detects tool and toolholder problems.

- Simulation enables previewing machining process to find efficiencies and correct issues before production starts.

Project Details

Avans Machine, Inc. in Scottsboro, Alabama serves industries including pharmaceutical/medical, aerospace, space, and defense.

The company has a reputation for taking on any job, no matter how big or small, and for producing high quality parts.

Mastercam Channel Partner, CAD/CAM Solutions, is always there for training and support.

Avans uses 40 CNC machines, including multiaxis mills and lathes, wire EDMs, and nine-axis machines. CNC programming is done by a team led by programmer Trevor Hall.

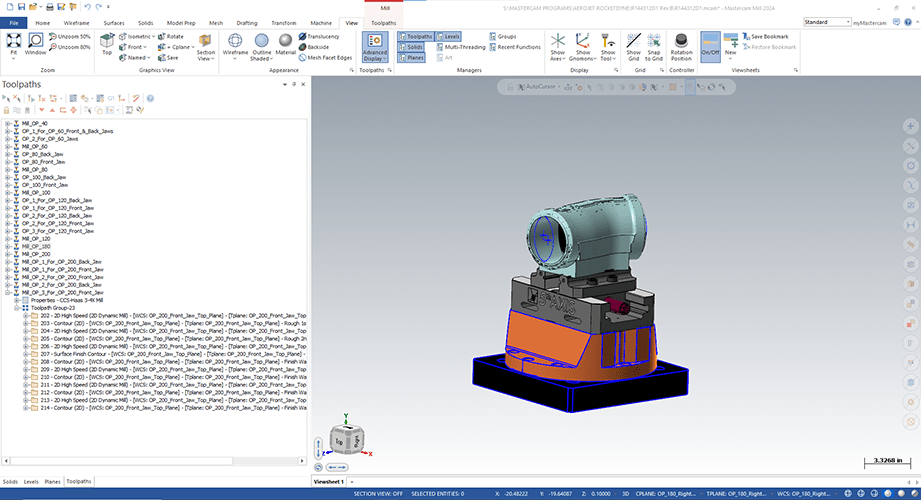

They needed a more universal CAM software system to meet customer needs, so Avans turned to CAD/CAM Solutions, Inc. in Huntsville, Alabama for help. Sales and solution expert, Brian Kadow, recommended Mastercam for its flexibility and robust set of programming tools, including Backplot to check toolpaths for issues; Verify for efficient stock removal; and Machine Simulation to see the part being machined in real time.

They also use Mastercam to develop custom fixturing.

The only problem was the programmers didn’t have any experience with Mastercam. Kadow reassured them. The software is intuitive, CAD/CAM Solutions offers in-person training classes, and they could be to Avans in under an hour for on-site support if needed.

Mastercam’s ease of use, and its ability to think like a machinist helped the company get up to speed quickly. Especially important for a shop with such a wide variety of jobs is Mastercam’s emphasis on streamlining workflow. Automations such as importing families of operations customized to individual parts, the ability to create standard part and toolpath geometries, and the ability to use batch processing enable Avans to add new parts or part iterations quickly and confidently to its production mix.

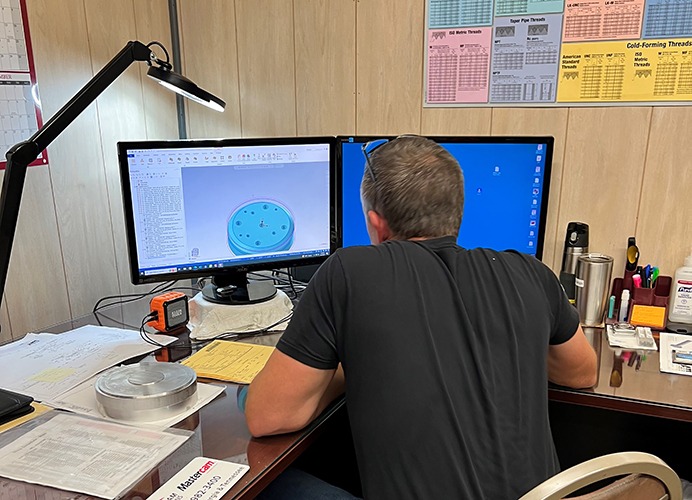

Avans programmer reviews toolpaths using Mastercam’s Verify and Backplot features.

Across the board the programming team’s favorite feature is OptiRough, powered by Mastercam’s Dynamic Motion technology. It enables a more efficient, collision-aware roughing strategy. Using bi-directional cutting motion and deeper cuts to remove material, cycle times, tool wear, and breakage are reduced. Dynamic Motion technology also helps the tool move at a consistent speed, and is kept at a consistent depth, and changes to the stock size and shape automatically which results in necessary toolpath changes.

Many factors are taken into consideration for each part, including material, complexity, quality requirements, and machining environment.

Before releasing programming to the floor, Hall and his team use the Verify and Backplot functions to catch any issues and ensure what was programmed will run as expected.

“I like being able to make adjustments as I watch the simulation,” says programmer Adam Wright.

Quick Facts

Product Used: Mastercam Multiaxis, Mill-Turn, Mill 3D, Lathe, and Wire

Industry: Aerospace & Defense, Medical