Benefits of 5-Axis Curve Machining

5-axis curve machining offers significant advantages in the manufacturing process, particularly in terms of precision and efficiency. By allowing the tool to approach the workpiece from multiple angles, manufacturers can achieve intricate designs that were previously difficult or impossible to produce with traditional machining methods.

Moreover, the enhanced tool axis control leads to improved surface finishes and reduced machining time. This results in lower production costs and higher quality outputs, making 5-axis machining a valuable investment for manufacturers looking to streamline their operations and improve their product offerings.

Integrating CNC Software with 5-Axis Machining

The integration of advanced CNC software, such as Mastercam, with 5-axis machining systems is crucial for maximizing the capabilities of multiaxis machines. This software enhances programming efficiency and enables users to create complex toolpaths that optimize cutting strategies.

With features designed specifically for 5-axis operations, manufacturers can automate processes, reduce programming errors, and enhance overall productivity. The seamless interplay between software and hardware ensures that manufacturers can fully leverage the technological advancements in machining.

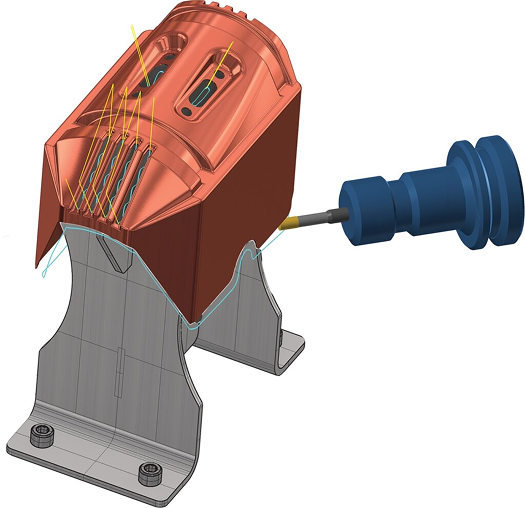

Tool Axis Control in 5-Axis Machining

Tool axis control is a critical feature in 5-axis machining that distinguishes it from traditional machining methods. This control allows operators to adjust the angle of the cutting tool in relation to the workpiece, which is essential for achieving high precision in complex geometries.

Effective tool axis control not only enhances the quality of the finished product but also extends tool life by reducing wear and tear. By mastering this aspect, manufacturers can significantly improve their machining capabilities and ensure consistent results across various applications.

Applications of 5-Axis Curve Machining

5-axis curve machining is utilized across various industries, including aerospace, automotive, and medical manufacturing. Its ability to produce complex shapes and high-precision components makes it ideal for applications that demand stringent tolerances and intricate designs.

For instance, in the aerospace industry, 5-axis machining is used to create lightweight yet strong components that contribute to fuel efficiency. Similarly, in the medical field, it enables the production of custom implants and surgical instruments tailored to specific patient needs, showcasing the versatility and importance of this machining technology.